MINIATURE HIGH SPEED AND HIGH EFFICIENCY AIRFOIL BEARING TURBO BLOWER

10-40Kpa

UP TO

40%

Energy Savings

OVER

50%

Smaller Footprint

UP TO

87%

Turndown

BELOW

80dBA

Low Noise

| Energy-saving comparison of miniature airfoil bearing turbo blower | |||||

| MODEL |

Power for operation |

Substitute power |

power saving | ||

|

per hour |

24 hours a day | 365 days | |||

| HKG7.5 | 7.5 | 11 | 3.5 | 84 | 30660 |

| HKG15 | 15 | 22 | 7 | 168 | 61320 |

| HKG22 | 22 | 30 | 8 | 192 | 70080 |

| HKG30 | 30 | 45 | 15 | 360 | 131400 |

| HKG37 | 37 | 55 | 18 | 432 | 157680 |

| Parameters of miniature airfoil bearing turbo blower | ||||||

|

Power(kpa) FLow rate(m3/min) |

HKG7.5 | HKG15 | HKG22 | HKG30 | HKG37 | HKG45 |

| 15 | 22 | 39 | 57.5 | 78 | 95.5 | 121 |

| 20 | 20 | 37 | 52 | 74 | 89 | 115 |

| 25 | 16 | 30 | 43 | 60 | 74 | 95.5 |

| 30 | 14 | 26.4 | 38.3 | 51.3 | 63 | 76 |

| 35 | 12 | 23 | 33 | 45 | 58.5 | 69 |

| 40 | 19 | 29 | 38.5 | 48 | 58.5 | |

Specifications not listed in the table can be customized to your requirements.

Miniature -high speed and high efficiency airfoil bearing turbo blower (referred to as air turbo blower) is increasingly widely used in the sewage treatment industry, its core technology through air suspension bearing to achieve contactless operation, combined with intelligent control system, significantly improve the efficiency of sewage treatment and reduce energy consumption.

I. Core application scenarios

a. Oxygen for aeration

By transporting compressed air to the aeration tank, the airfoil bearing turbo blower increases the concentration of dissolved oxygen in the water and promotes microbial degradation of organic matter. Its precise air volume adjustment ability (such as adjusting the speed through the inverter) can dynamically match the needs of different working conditions, avoiding the energy waste caused by excessive aeration of traditional equipment.

b. Mix and stir

Through the air bubble and water flow disturbance, the airfoil bearing turbo blower can evenly disperse the suspended matter in the sludge and enhance the solid-liquid contact efficiency. For example, in the MBR (membrane bioreactor) process, its efficient mixing capability reduces membrane contamination and extends equipment life.

c. Backwash and sludge treatment

In the backwash phase of the filter or membrane assembly, the air float blower provides high pressure air to wash away impurities and restore the efficiency of the treatment unit. In one case, the airfoil bearing turbo blower replaced the traditional Roots blower, the backwash efficiency was increased by 30%, and the noise was reduced to less than 80dB.

1. Noise level below 80 dBA, ensuring quiet operation, much more environmentally friendly.

2. Significant energy-saving effects:

- 25%-50% more energy-efficient than Roots blowers.

- 20%-40% more energy-efficient than ring blowers.

- 20%-30% more energy-efficient than screw blowers.

3. Oil-free medium, no need for lubrication oil, resulting in low operating costs.

4. Whole set skid-mounted design, independent Siemens PLC control, Siemens touchscreen, and high level of intelligence.

5. High-precision integration, compact size, occupying smaller space.

6. Maintenance-free, only requires filter replacement every three months, with each filter costing less than 50 euros, ensuring low maintenance costs. Filters can be replaced during operation without the need for shutdown.

7. Can be set for timed start and stop.

8. Two mode options: speed mode and flow mode.

9. Airfoil bearings with a lifespan of up to 20 years, ensuring long-term operation without mechanical wear and no decrease in efficiency.

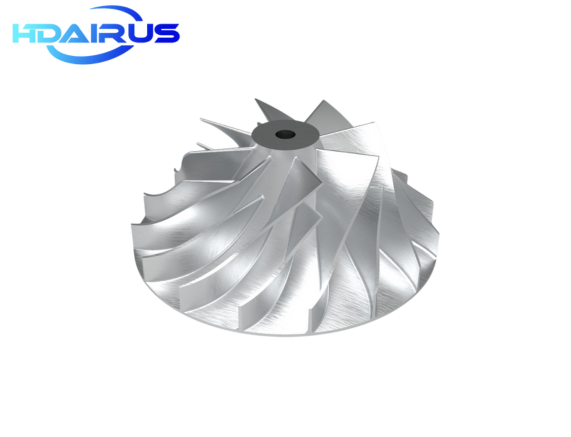

10. Utilizes aerospace materials, five-axis machining for high-precision ternary flow impellers, and direct drive by high-speed permanent magnet motors, achieving speeds up to 30,000 RPM with no energy efficiency loss and motor efficiency as high as 98%.

11. 12-month warranty since the customer receives the product, with a replacement-only policy during the warranty period.

12. Domestic screens allow for remote monitoring via computer or mobile phone anytime, anywhere.

13. OEM services are available at an additional 20% cost.

1. Supply oxygen for aeration

This is the most core application scenario of the air blower. By transporting compressed air to aeration tank, the concentration of dissolved oxygen in water is increased, and the degradation of organic matter by microorganisms in activated sludge is promoted.

Accurate oxygen supply: The airfoil bearing turbo blower uses a frequency converter to adjust the speed, achieving a wide range of 50%-100% air volume adjustment, and dynamically matching the needs of different working conditions.

2. Mix and stir

Through bubble and water flow disturbance, the uniform mixing of sludge and sewage is promoted, and the biological reaction efficiency is enhanced.

Reduced membrane contamination: In the MBR (Membrane bioreactor) process, the efficient stirring capacity of the air float blower prevents sludge deposition and extends the life of the membrane components.

Improve solid-liquid contact: high-speed air flow drives the uniform distribution of suspended matter, increases the reaction contact area, and accelerates the decomposition of pollutants.

3. Backwash

It is used to clean the processing units such as filter and membrane components and restore their filtration performance.

High-pressure air scour: The air blower provides high-pressure gas to effectively remove impurities from the surface of the filter material or film.

4. Sludge treatment and recycling

Sludge suspension control: prevent sludge deposition through airflow disturbance, improve solid-liquid separation efficiency, and reduce treatment energy consumption.

Sludge dewatering assistance: In the process of sludge concentration or dewatering, the air float blower provides stable airflow support to optimize the treatment effect.

5. Special scenario adaptation

High altitude areas: By adjusting the air volume coefficient, to ensure a stable oxygen supply under low pressure environment.

Industrial wastewater treatment: For high-concentration wastewater such as paper making and chemical industry, the high-pressure adaptability and corrosion resistance design of the air float blower ensure the treatment stability.

RETURN

RETURN