Product Introduction

High-End Maglev Engineering

The magnetic levitation high-speed centrifugal blower is a new type of high-efficiency, energy-saving and environmentally friendly blower formed by integrating the magnetic levitation bearing technology and high-speed motor technology into the traditional blower, with the significant advantages of simple structure, high-efficiency and intelligence, integration, simple operation and maintenance, and low operating costs.

Technical Specifications

Key Parameters & Energy Efficiency

| Machine Model | Suction Flow | Pressure (kPa) | Motor Power (kW) |

|---|---|---|---|

| HMGB55 | 28-19 | 30-50 | 55 |

| HMGB75 | 70-30 | 40-120 | 75 |

| HMGB90 | 100-40 | 40-120 | 90 |

| HMGB150 | 150-57 | 40-120 | 150 |

| HMGB200 | 220-84 | 40-120 | 200 |

| HMGB400 | 350-130 | 50-120 | 400 |

| Compare Item | Maglev Turbo Blower | Roots Blower |

|---|---|---|

| Blower Input Power | 75 kW | 150 kW |

| Blower Efficiency | 85% | 55% |

| Annual Power Cost | 648,000 kW/h | 1,296,000 kW/h |

| ANNUAL ENERGY SAVING: 648,000 kW/h | ||

Engineering Excellence

The Core of Magnetic Levitation

Ultra-High Speed PM Synchronous Motor

Delivering maximum torque with minimal energy footprint.

Aerodynamic High-Efficiency Impeller

Precision-engineered for optimized airflow and superior compression.

Frictionless Magnetic Bearing System

Eliminating mechanical wear for near-infinite service life.

Integrated Intelligent VFD System

Precise frequency control for seamless performance adaptation.

100% Oil-Free Design

Ensuring a clean process environment with zero risk of contamination.

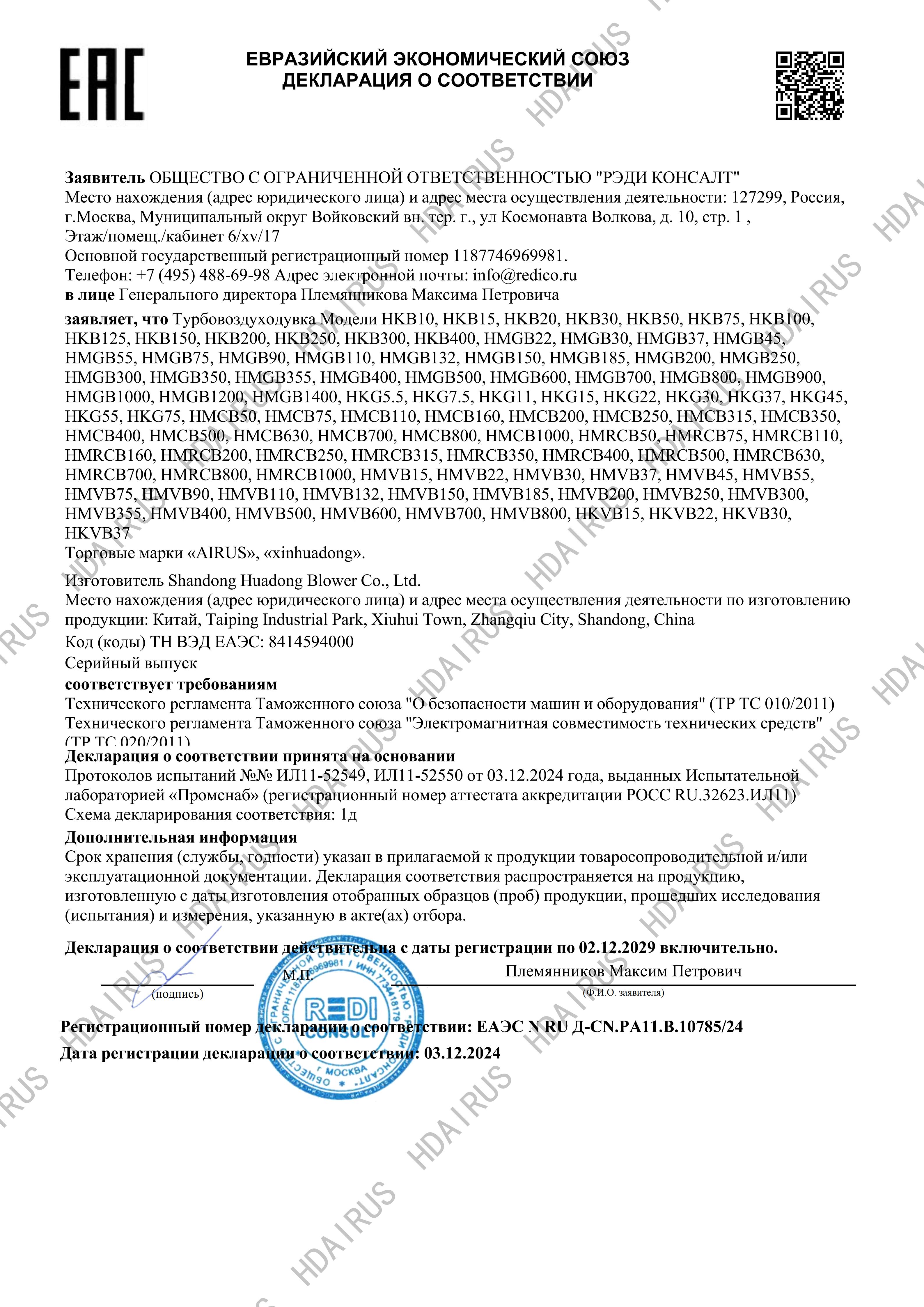

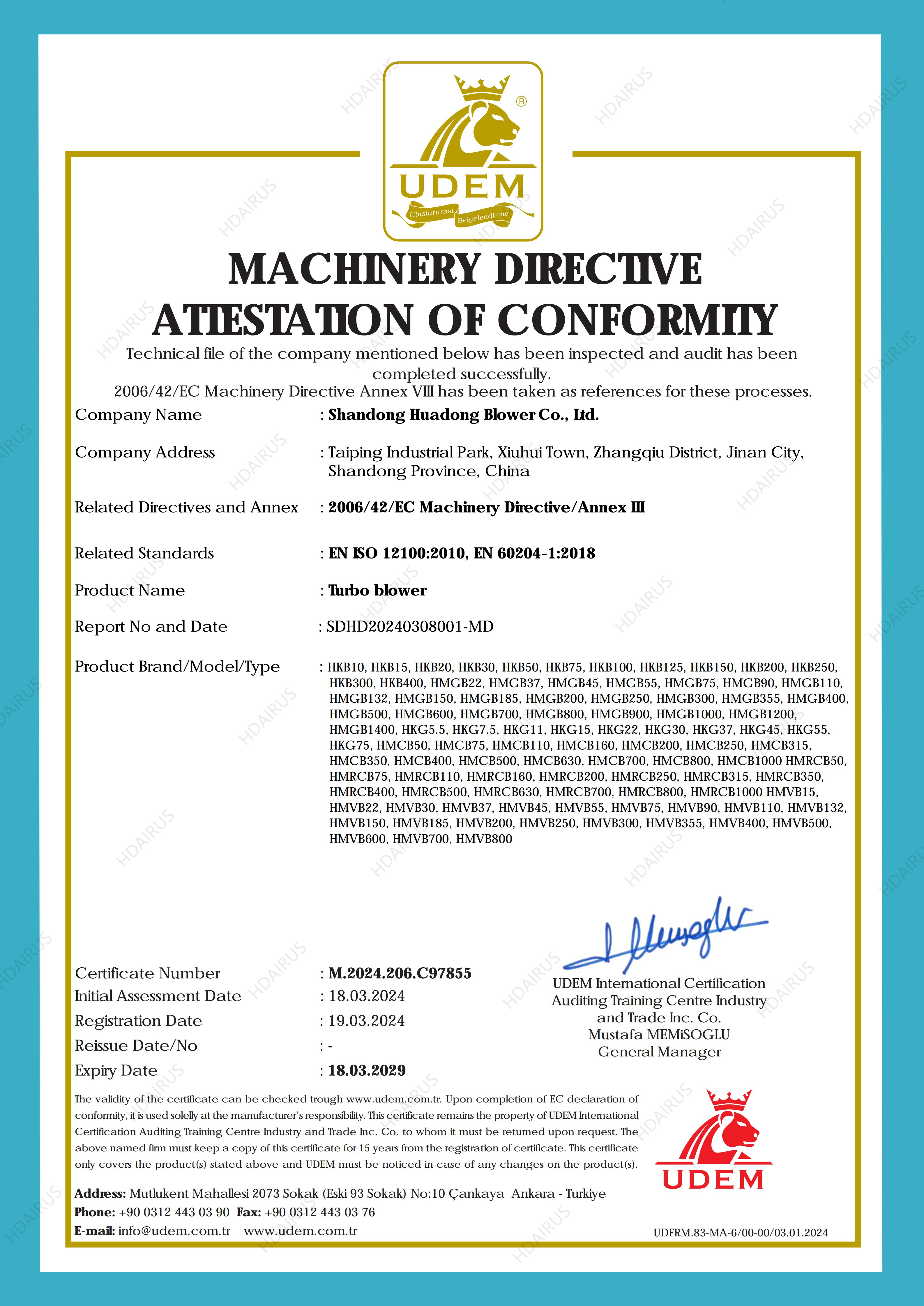

Compliance & Trust

Industrial Standards Certified

Industrial Deployment

Where Power Meets Precision

Service & FAQ

Operational Support