Product Introduction

High-End Maglev Engineering

Magnetic levitation high-speed centrifugal air compressors combine magnetic bearing technology with high-speed motors to deliver oil-free, contactless, and highly efficient compression.

They feature low noise, low vibration, intelligent control, simple maintenance, and reduced operating costs. Widely used in pharmaceuticals, food, textiles, power, glass, and other industries, they provide reliable performance with significant energy savings.

Technical Specifications

Key Parameters & Energy Efficiency

| Model | Flow Range (m³/min) | Pressure Range (bar) | Power (kW) |

|---|---|---|---|

| HMC2.0-160 | 39 - 67 | 1.0 - 2.5 | 160 |

| HMC2.0-200 | 56 - 86 | 1.0 - 2.5 | 200 |

| HMC2.0-315 | 91 - 132 | 1.0 - 2.5 | 315 |

| HMC2.0-500 | 138 - 202 | 1.0 - 2.5 | 500 |

| HMC2.0-800 | 216 - 313 | 1.0 - 2.5 | 800 |

| HMC3.0-110 | 24 - 35 | 2.0 - 3.5 | 110 |

| HMC3.0-160 | 33 - 50 | 2.0 - 3.5 | 160 |

| HMC3.0-400 | 87 - 128 | 2.0 - 3.5 | 400 |

| HMC3.0-630 | 137 - 196 | 2.0 - 3.5 | 630 |

| HMC3.0-800 | 174 - 251 | 2.0 - 3.5 | 800 |

Engineering Excellence

The Core of Magnetic Levitation

High Operating Efficiency

Delivering up to 48% energy savings under partial load with integrated remote diagnostic monitoring.

100% Oil-Free Design

Eliminating oil management systems to cut maintenance costs by 50% and prevent efficiency loss.

Ultra-Lightweight Construction

Advanced compact design at just one-fifth the weight of conventional compressor units.

Ultra-Quiet Static Operation

Maintaining a noise-optimized environment with operating levels below 70 decibels.

Intelligent Soft-Start Technology

Reducing starting current to just 2 amps for minimal grid impact and enhanced safety.

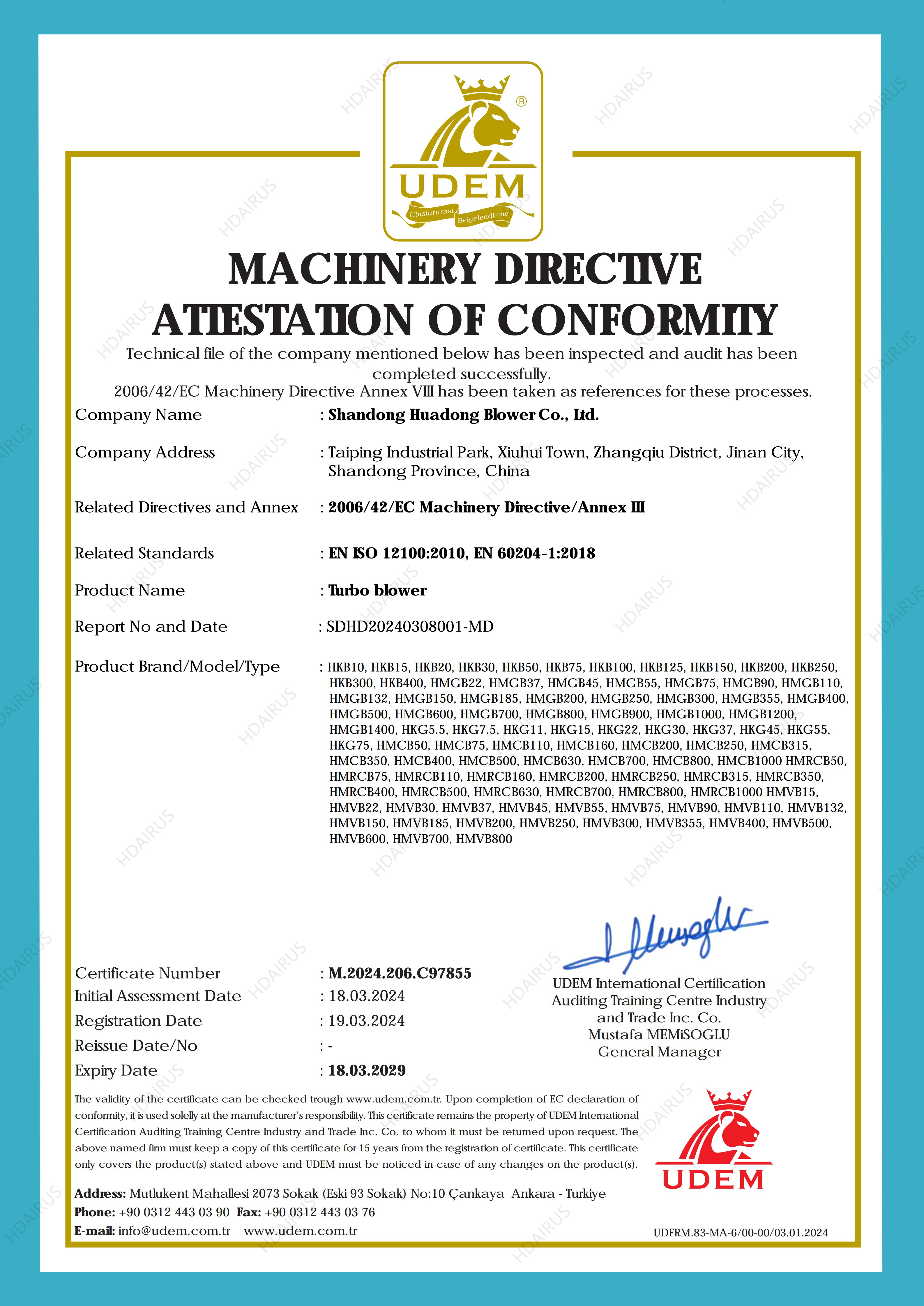

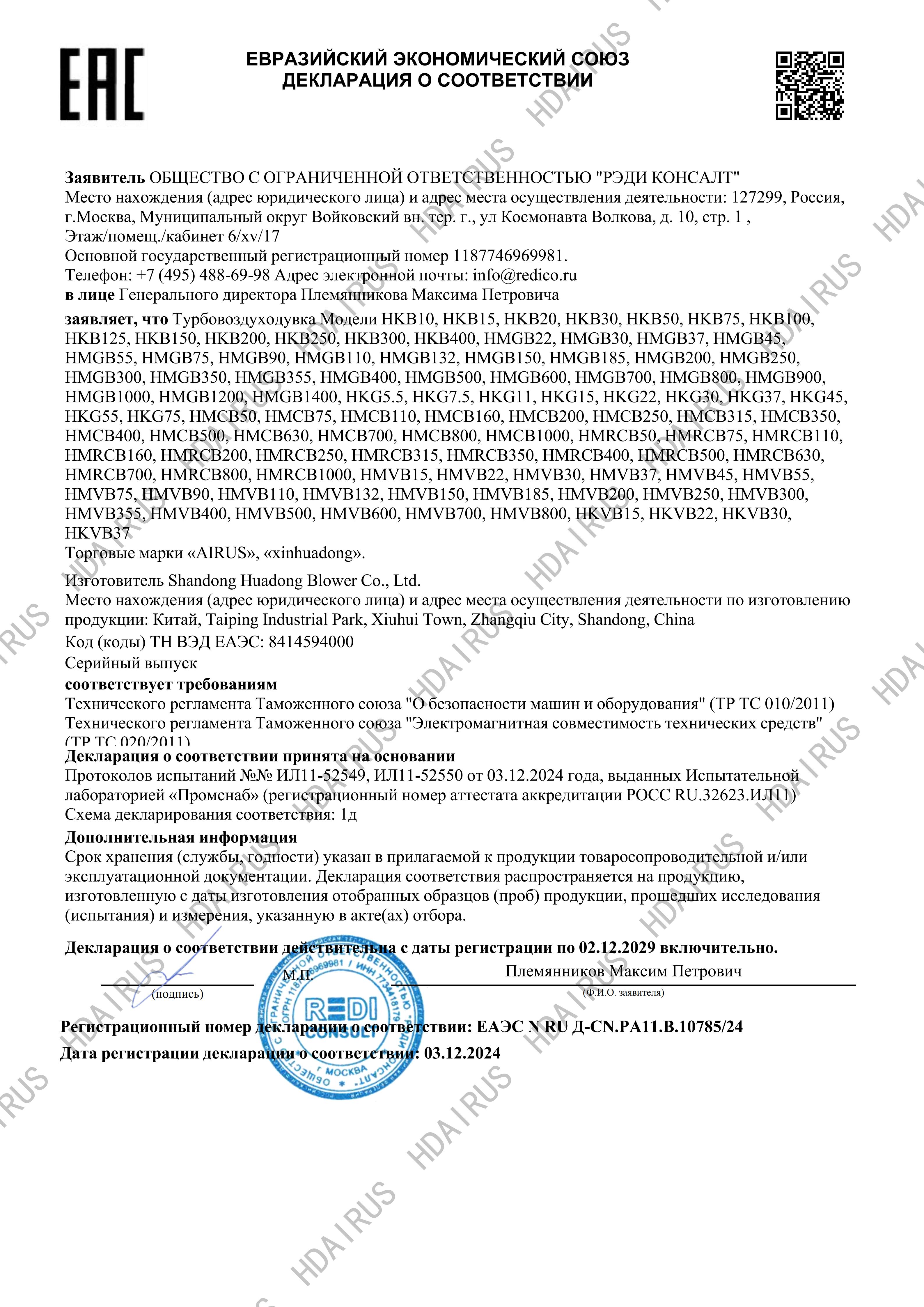

Compliance & Trust

Industrial Standards Certified

Industrial Deployment

Where Power Meets Precision

Service & FAQ

Operational Support